电渣熔铸产品的优点

Product Advantages

01

Low content of non-metallic inclusions and harmful elements, with small and uniform distribution of inclusions, and pure microstructure of castings;

02

Mechanical properties are isotropic and can meet the performance requirements of forgings;

03

The impact toughness, fracture toughness, and fatigue resistance are significantly improved, with a high ability to generate and expand crack lines, improving the safety of use;

04

The material density has significantly increased, greatly improving the ability to resist cavitation and mud sand wear, and extending the service life of castings. The casting performance is not lower than that of forgings of the same material;

05

Ultrasonic testing can meet the first level requirements of national standards, European Community standard CCH70-4, and American Foundry Association standard ASTM A609, improving the safety of castings during use;

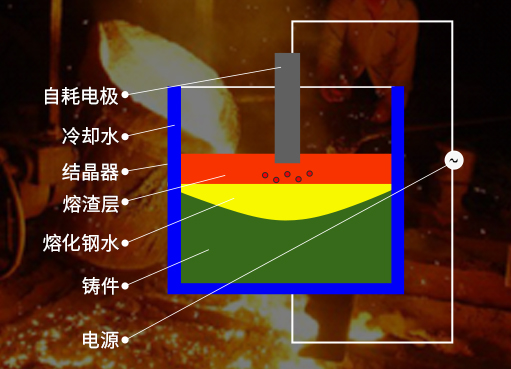

Electric slag casting process:

At the beginning of electroslag casting, a certain height of slag layer is first formed at the bottom of the crystallizer. The slag layer can conduct electricity and has a certain slag resistance. When the consumable electrode of the power supply is immersed in the slag layer, a strong current is formed in the slag pool, and the heat generated increases the temperature of the slag.

When the temperature of the slag exceeds the melting point of the consumable electrode, the consumable electrode is melted, and the melted molten steel passes through the slag pool in the form of droplets from the electrode surface under the action of gravity.

In this process, the slag pool absorbs harmful elements and inclusions in the molten metal, and the purified molten steel gathers at the bottom of the slag pool to form a molten pool, which solidifies in the mold cavity with forced cooling, forming the casting body.

During the casting process, the melting of consumable electrodes, purification and filling of molten steel, and sequential solidification are continuously carried out in a state isolated from air until the crystallizer is fully filled, completing the entire casting process.